A standard pool has 16 phases of construction, though variations exist. The agenda below is typical of a standard pool build with an expected completion time of 8 -10 weeks. Completion times will vary due to unique requirements of the site, weather conditions or scope of work. Excavation – Steel & Plumbing Short Stub – Steel Bonding Inspection – Gunite – Plumbing Gas – Electric Rough Inspection – Pre Grade – Deck Bonding Inspection – Tile – Coping – Equipment Set – Decking – Electric – Final Clean – Plaster Preparation – Plaster – Start Indoctrination – Final Inspection.

-Excavation-

CPC will use a trackhoe to excavate your pool. The elevation and location of the pool are pre-approved prior to excavation, as well as the appropriate access route and the final location of the pool equipment. The CPC crew will excavate and form the pool based on the dimensions outlined in the customer’s contract, approved construction drawing, and construction walkthrough Heavy machinery is used during excavation. It is likely if not guaranteed, that grass, concrete or other lot materials within the access route will be compressed or damaged during the excavation process. Though the CPC crew will take as much care as possible, the customer is advised that Carolina Pool Consultants LLC does not assume responsibility for resulting damage to underground sprinkler systems private lines, grass, concrete, or other ground material in the access path. Prior to excavation, be certain that access is unblocked by any trees, shrubbery, air conditioning units or other items of import that may obstruct clear access to the excavation site.

Steel &Plumbing Short Stub

The CPC Steel Crew uses rebar to bend and form a steel cage in the shape of the pool. They will form the top perimeter, walls, Floors, spa, skimmers, and benches.

The Steel Crew is responsible for bonding the steel cage. Following completion of the bonding inspection, the steel crew will set the skimmers, drains and returns. If the build requires a spa, the crew will install spa jets, airline, and drains.

Note: Steps do not require rebar for reinforcement and are formed completely in the Gunite Stage utilizing trowels.

Steel Bond Inspection

Upon completion of the steel cage, the Carolina Pool Consultants scheduling office will contact the proper local municipality for a licensed bonding inspection.

-Gunite-

CPC POOLS GUNITE is concrete conveyed through a hose and pneumatically projected at high velocity onto the excavated and steel framed surface. In our dry-mix process, the dry sand and cement mixture is blown through a hose using compressed air, with water being injected at the nozzle to hydrate the mixture, immediately before it is discharged. It gives structure, reinforces and stabilizes all of our projects.

The nozzleman is key, he controls the addition of water at the nozzle. The water and the dry mixture is not completely mixed, but is completed as the mixture hits the receiving surface. We have the most skilled nozzlemen that adjust the water content instantaneously allowing more effective placement, especially when the project needs reinforced sections.

The Gunite Crew will require access to on-site water for the gunite equipment to function. During this phase, the gunite will be shot to form the pool shell. The shell will have a rough finish – an intentional result, as the plaster will adhere and bond to the surface more evenly.

Plumbing & Gas

The plumbing and electrical crew will set all of the customer’s plumbing and electrical underground conduit lines to the final pool equipment location. All plumbing and electrical lines will be installed in trenches dug with small trackhoe.

Electric Rough Inspection

Upon completion of the plumbing/electric (and gas) phases, the CPC Scheduling Office will arrange for a formal electric rough inspection with the local municipality inspector. DO NOT fill any open trenches until this inspection has been approved and signed by the inspector.

Pre-Grade & Wire for Deck Bond Inspection

A Pre-Grade will be completed after a passed underground inspection to backfill the trenches and to prepare the deckarea for concrete or pavers. In addition, the CPC grader will install a wire grid around the perimeter of the pool shell wherever decking is approved to be installed. After installation, the CPC Scheduling Office will arrange for a deck bond inspection to take place with the local municipality.

Tile & Coping

After the concrete has cured for a few days, work will resume with the Tile & Coping Crew. The crew will set a six-inchband of waterline Tile and will install the coping around the beam of the pool. If the customer has a spa, the crew will also install the slate spillway. Any additional stone or Tile work will be completed during this phase.

Equipment Set

One of Carolina Pool Consultants’ official partners will send a representative to the property to install the necessary equipment outlined in the customer’s contract. All electrical underground, preliminary gas lines, and plumbing lines will have been properly installed, inspected and covered before this phase. The representative will take approximately a half-day to install the pool’s pump, primary filter, heater if needed, inline chlorinator or salt and all additional valves. In addition, the representative will set the lights for an electrician to address in a future stage. DO NOT touch any pool equipment prior to the introductory education phase later in the pool construction process.

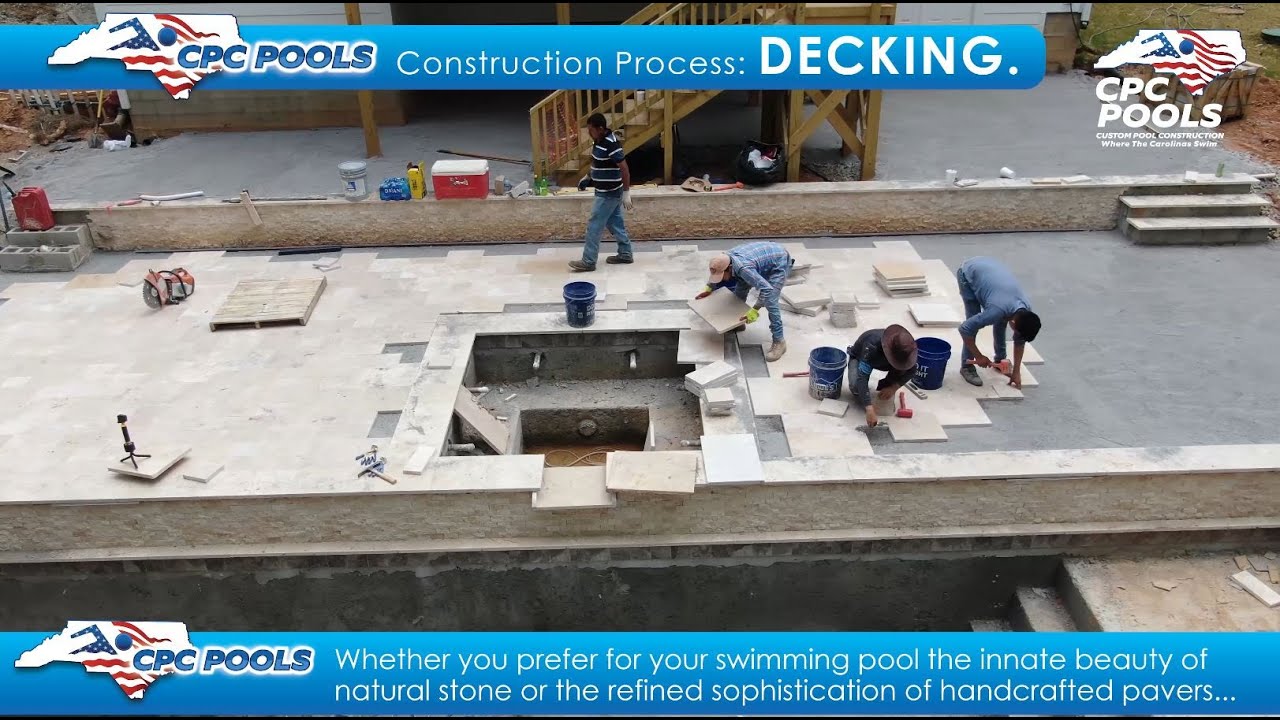

Decking

Deck will be installed with a quarter inch pitch compliant with industry standards sloping away from the pool. The deck contractor will install any drainage included in the customer’s contract. Typically, concrete decking is formed and poured within a two-day period. Paver or any other hard scape selections will be installed with a sub-base and a sand/rock screening base.

Electrical

The electrical crew will set all of the customer’s pool equipment in addition to running all the electrical lines to the equipment from the pool. The electricians will require access to the home to properly tie in the power lines to the pool equipment. If the customer has purchased an electrical sub-panel, it will be installed during this phase. During this phase, all lighting installed within the pool will be properly powered.

Final Clean

A final clean will follow the completion of the formal pool construction. All construction debris will be removed from the site and a rough, machine grade will be completed with dirt on hand. NO additional dirt will be brought in at this point.

Plaster Preparation

The CPC plaster crew will arrive the day before the plaster is scheduled to thoroughly clean the pool shell prior to the plaster application. During this process they will be power washing the gunite, cleaning out any loose debris, and laying out plastic tarp depending on weather conditions. DO NOT continue to water down your pool shell after the plaster preparation has concluded.

Plaster

On plaster day, the CPC crew will arrive in the morning and begin applying the plaster mix agreed upon in the customer’s contract. The process is time-consuming and can lead to many mixed results if not performed correctly or in the right conditions, so it is imperative nothing interferes with the crew during the job.

Filling the Pool

Upon completion of the plaster, it is the homeowner(s) responsibility to fill the pool with water. If a hose is onsite, the plaster crew will place it in the pool to begin filling. If the customer elects to transport the water in to fill the pool, it is the customer’s responsibility to the schedule the water to be delivered. The CPC Scheduling Office can assist in regards to where water can be sourced. DO NOT stop the water flow after starting to fill the pool for any reason. Continue filling the pool until the water level rises to the center of the tile line. It is the homeowner(s) responsibility to brush the entire pool surface thoroughly AT LEAST TWICE A DAY to homogenize chemicals and remove plaster dust. This process will be included in your introductory education.

Startup / Pool School

The CPC Scheduling Office will contact the customer to plan an introductory education appointment, otherwise known as ‘pool school’. This meeting is the best place to ask any questions concerning the pool’s operation or care. Please arrange for all homeowners to attend, prepared to take notes. Training regarding how to operate the filter, pump, heater and all the valves will be covered.

Startup / Pool School

Carolina Pool Consultants, LLC will provide you with your Permit Number and Contact Information to call and schedule a final building inspection for your pool. It is the homeowner(s) responsibility to make sure all fence/door alarms meet all local building codes. Please contact the CPC Scheduling Office when the fence has passed inspection so that CPC can provide you with all information needed. It is recommended that final inspection be scheduled no later than 10 days after the plaster date.